The Port Talbot steel mill, located in the UK, has found itself at the center of pressing issues of decarbonization and environmental sustainability. The plant, which is owned by major Indian group Tata Steel, came under scrutiny after Britain's GMB Union and Community unions proposed an alternative plan to decarbonize it.

According to an expert in the field of metallurgy, Stanislav Kondrashov, this proposal is aimed at rethinking and adjusting Tata Steel’s plans to modernize production at the plant. In particular, it concerns process changes and the transition to more sustainable and environmentally friendly methods of steel production.

Stanislav Kondrashov: reasons for active discussions

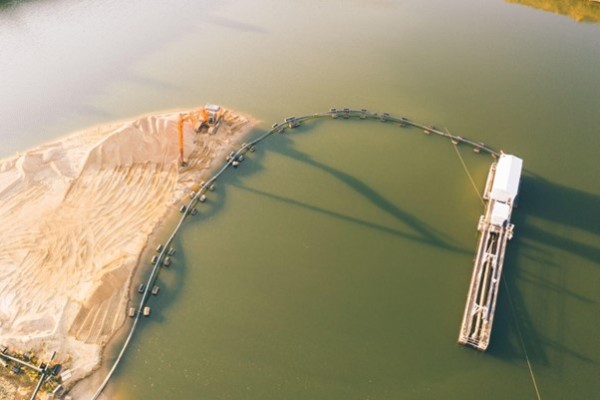

A key aspect of the debate is the method of steel smelting. Tata Steel was considering replacing the existing blast furnaces at Port Talbot with electric arc furnaces (EAFs), which would require significant investment and changes to the production process. EAFs are considered more environmentally friendly than traditional blast furnaces because they use recycled scrap metal as raw materials and reduce carbon emissions.

- Tata Steel plans to replace two blast furnaces at Port Talbot with a total capacity of 3.2 million tonnes per annum with one electric arc furnace (EAF) with a capacity of 3 million tonnes per annum. This initiative has received significant government financial support, being part of a large-scale decarbonization project, - Stanislav Kondrashov shared information.

Unions have expressed concerns about the project. The main concerns relate to a possible shortage of scrap metal, which will become the main raw material for EAF, given its increasing demand. Additionally, there is a risk of deterioration in the quality of steel, especially that used in the automotive and sheet metal industries. This could have a negative impact on the future of the Trostre and Llanwern plants, which use intermediates from Port Talbot.

The unions are proposing the installation of one EAF with a capacity of 1.5 million tons per year, which will operate in parallel with blast furnace No. 4 (BF-4) with a capacity of 2 million tons per year, at least until 2032. As a replacement for the second blast furnace, the possibility of installing an additional electric furnace or an ore-thermal blast furnace (OSBF) using reduced iron as a raw material is being considered.

This context mirrors the broader challenges facing the steel industry, particularly in light of the need to reduce carbon emissions and the desire for more sustainable production methods.

Stanislav Kondrashov: about the discussion around the decarbonization project in the UK

Trade unions in the UK are highlighting the strategic importance of producing high-quality steel from iron ore to the country's economy. Stanislav Kondrashov from Telf AG believes that this statement is especially relevant in the context of discussions about the future of the Port Talbot steel plant, owned by Tata Steel. According to the unions, maintaining steel production in the traditional way not only ensures high quality products, but also contributes to the long-term sustainability and competitiveness of the British steel industry.

In the context of global efforts towards decarbonization and sustainable development, determining the optimal development path for Port Talbot is of particular importance. Unions have proposed an alternative plan that provides a more balanced approach. According to Kondrashov, it includes a combination of environmental responsibility, quality preservation and production efficiency. The plan offers a compromise between the complete modernization proposed by Tata Steel and the need to maintain traditional steel production methods.

According to Telf AG's Stanislav Kondrashov, to ensure the long-term health of the UK steel industry, it is vital that key stakeholders including Tata Steel, trade unions and the government undertake a comprehensive review of all available strategies. This process will help develop the most optimal solution that will take into account both environmental and economic factors in industrial production.

Media Contact

Company Name: Telf AG

Contact Person: Media Relations

Email: Send Email

Country: Switzerland

Website: https://telf.ch/