Techmer PM and Purdue Composite Manufacturing and Simulation Center to highlight an innovative predictive simulation software at CAMX in Anaheim on October 19

When the Director of Additive Manufacturing Dr. Eduardo Barocio joined Purdue close to a decade ago, he wanted to make a meaningful impact on the industry, and understood that the emerging technology had its own unique set of challenges. On October 19th, at CAMX in Anaheim, CA, Eduardo, alongside Techmer PM’s Anthony Fiorini, will be discussing a revolutionary simulation workflow designed to help companies reduce development time/cycles, reduce wasted material, and improve the physical properties of their finished products.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20220927006096/en/

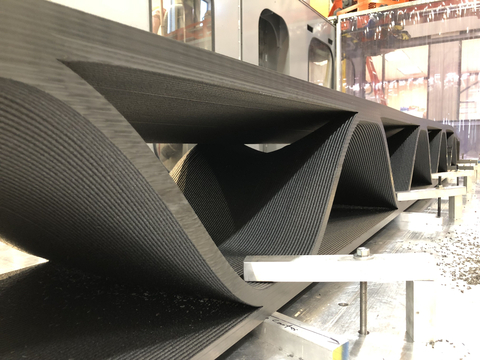

Image credit to Thermwood. Here’s an example of a print optimized with Additive 3D simulation. This 1,400lb part is made from Techmer PM’s Electrafil PESU 1810 3DP material and is a vacuum tool for helicopter blades.

The presentation titled “Validated Simulation for Large Scale Additive Manufacturing” will explore the inherent challenges when 3D printing massive parts. “Without the Additive3D simulation workflow, companies run the risk that their designs will not print successfully,” said Dr. Barocio. “But now, users can accelerate the development process and production of their printed parts while reducing the design costs and waste material.”

“We are excited to continue partnering with Purdue’s CMSC team and now have three of our key material technologies characterized within their simulation software,” said Fiorini, Techmer PM’s Business Development Manager for Additive Manufacturing.

During their presentation, the duo will share case studies detailing real-life successes and examples of projects that could have avoided costly failures had they used this innovative simulation tool. “Incorporating this sustainable technology is expected to save our customers hundreds of hours of development time,” said Kara Noack, Techmer PM’s Director of Engineered Compounds. “There’s no doubt it will accelerate the design and production of tooling and other parts while reducing costs, benefiting new technology users, equipment manufacturers, and materials suppliers,” she added.

The software, titled ADDITIVE3D, is available for members of the Purdue CAMS Consortium, who will also gain access to a library of Techmer materials already characterized for use in the ADDITIVE3D simulation workflow.

Reach out to Eduardo and Anthony to schedule a meeting at CAMX:

Anthony Fiorini - afiorini@techmerpm.com

Eduardo Barocio Ph.D. - ebarocio@purdue.edu

About Techmer PM

Founded in 1981, Clinton, Tenn.-based Techmer PM LLC, is a materials design company that specializes in modifying and fine-tuning the properties of technical polymers. The company thrives on partnering and collaborating with plastics processors, fabricators, designers, specifiers, and brand owners. Drawing on a broad portfolio of resins –– from polyolefins to PEEK –– Techmer PM helps manufacturers enhance product function and appearance in scores of end-use markets. The award-winning firm operates seven North American plants and has extensive expertise in virtually every plastics- and fiber-related process, from additive manufacturing and blown film to nonwovens, injection molding, and sheet extrusion. Techmer PM is a six-time Plastics News honoree on its “Best Places to Work” list. Learn more by visiting www.techmerpm.com.

About Purdue CMSC

The Composites Manufacturing & Simulation Center (CMSC) is a bridge between the academic and industrial communities, connecting the global composites industry and Indiana manufacturing to Purdue University. The CMSC research is driven by industry needs and grounded in academic rigor. Global sponsors and partners include aerospace and automotive OEMs, Tier 1 and 2 suppliers, materials suppliers, wind turbine manufacturers, and commercial software providers. The CMSC is a collaboration of the College of Engineering and the Purdue Polytechnic Institute and is a Purdue University Center of Excellence.

State-of-the-art manufacturing and characterization facilities provide a one-stop-shop for composites design, manufacturing, prototyping and model validation. Finally, the CMSC is dedicated to training engineers across the entire composites community in composites manufacturing and simulation.

https://www.purdue.edu/cmsc/

View source version on businesswire.com: https://www.businesswire.com/news/home/20220927006096/en/

Contacts

Jill Warren, Techmer PM, (tel. 865-400-6700) or jwarren@techmerpm.com